Affiliates

Affiliates

How to Choose the Right Wood Packaging for Your Products?

Choosing the right wood packaging for your products is crucial. The right choice impacts your brand's image and product integrity. Renowned wood packaging expert Dr. Michael Taylor once stated, "The right packaging can elevate a product beyond its physical presence." His insight highlights the significance of making an informed decision.

Wood packaging offers durability and sustainability. It's not just about protection; it also reflects your brand's values. Customers today appreciate eco-friendly solutions. However, selecting the wrong type can lead to damage. Each product has unique needs, and understanding these is essential.

Consider the environmental impact. Not all wood packaging is created equal. Some materials are sourced unsustainably, which can hurt your image. Striking the balance between cost and quality often presents challenges. As you explore options, reflect on both aesthetics and functionality. The perfect wood packaging should serve its purpose while aligning with your brand's vision.

Understanding the Importance of Wood Packaging for Products

Wood packaging plays a vital role in the protection and preservation of products. According to a report from the International Wood Products Association, over 30% of goods transported globally use wooden packaging materials. This packaging is not just functional; it also impacts sustainability efforts. Wood is renewable and can be recycled, providing an eco-friendly solution in an industry increasingly focused on reducing waste. Yet, sourcing wood responsibly remains a challenge.

The effectiveness of wood packaging can vary significantly. Research indicates that nearly 20% of products suffer damage during transit due to inadequate packaging. Using the wrong type or insufficient material can lead to losses. It's critical to understand the specific needs of your product. For example, fragile items often require more robust solutions. A mix of cushioning materials may also be necessary. Many businesses overlook these details, which can lead to regrets later on.

Choosing the right wood packaging is not only about safety but also about brand image. Companies that invest in effective packaging see a 15% increase in customer satisfaction, according to recent surveys. However, many fail to recognize this. They may prioritize cost over quality. In doing so, they undermine their reputation and risk significant financial losses.

How to Choose the Right Wood Packaging for Your Products?

| Packaging Type | Material | Weight Capacity (lbs) | Eco-Friendliness | Cost ($) |

|---|---|---|---|---|

| Pallet | Softwood | 2500 | Yes | 15 |

| Wooden Crate | Hardwood | 1600 | Yes | 80 |

| Wooden Box | Plywood | 2000 | Yes | 60 |

| Wooden Pallet Box | Softwood | 3000 | Yes | 100 |

| Wooden Transport Crate | Spruce | 2200 | Yes | 70 |

Types of Wood Packaging Solutions Available on the Market

When selecting wood packaging solutions, consider the types available in the market. Pallets are commonly used for shipping goods. They offer solid support for heavy loads. However, improper pallet choice can lead to product damage. Choosing the right size and quality matters immensely.

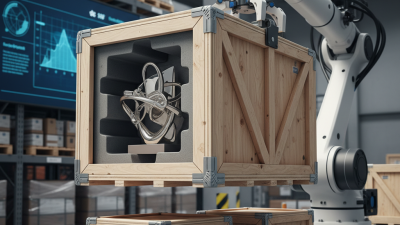

Crates are another option for businesses. These wooden boxes provide extra protection during transportation. They come in various designs. Customization options exist, but they can be costly. It's essential to evaluate if the investment justifies the enhanced security.

Finally, wooden dunnage is often overlooked. It helps stabilize products within larger containers. You might think this is a minor detail, but it prevents movement. However, sourcing the right wood type is critical. Not all woods provide the same level of durability. Reflecting on your specific needs may uncover new possibilities.

Factors to Consider When Choosing Wood Packaging Materials

When selecting wood packaging, several factors play a crucial role. One key consideration is the type of wood used. Different woods have varying strengths and levels of durability. Additionally, the wood should be sourced sustainably to minimize environmental impact. Considering the weight of your products is essential as well. Heavier items may require sturdier packaging, while lighter products need less robust options.

Another important factor is the packaging's design. It should complement your product's size and shape. Custom designs can enhance protection and aesthetics, making your product more appealing. Be mindful of the dimensions; excessive space can lead to movement and potential damage. On the other hand, if it's too tight, it may cause scratches or dents.

Moreover, compliance with regulations is often overlooked. Depending on the destination, certain guidelines dictate the treatment of wooden materials. It's crucial to research these requirements to prevent issues at customs. Lastly, consider cost; sometimes, opting for cheaper options can lead to higher long-term expenses. Balancing quality and price is key in this decision-making process.

Evaluating the Environmental Impact of Wood Packaging

When selecting wood packaging, its environmental impact should be a priority. According to the Forest Stewardship Council, forest management practices significantly influence the sustainability of wood products. Over 2.5 billion trees are cut for various uses annually. This highlights the importance of sourcing wood from certified, sustainable forests.

Many companies overlook the life cycle of wood packaging. From harvesting to disposal, each stage contributes to carbon emissions. Reports show that wood packaging can store carbon, offsetting some of these emissions. It's essential to consider how long the packaging will last and how it can be reused or recycled.

Tips: Choose suppliers committed to sustainable practices. Look for certifications like FSC or PEFC. Explore options like engineered wood products, which use less raw material while maintaining strength. Evaluating these aspects will lead to more eco-friendly choices. However, not all wood packaging is equal; consider its full environmental cost.

Regulations and Standards for Wood Packaging Compliance

Choosing the right wood packaging involves navigating complex compliance regulations. The International Plant Protection Convention (IPPC) mandates specific treatments for wood packaging. Non-compliance can lead to fines and product delays. In 2022, about 30% of shipments faced inspection due to inadequate packaging. This statistic stresses the importance of adhering to standards.

Ensure your packaging meets the ISPM 15 standard. This requires heat treatment or chemical fumigation of wood. It prevents the spread of pests across borders. Visual indicators like stamps help in identifying compliant products. More than 80 countries have adopted this standard, reinforcing its global significance.

Tips: Always verify your suppliers' certification. Packaging that fails to meet regulations can create issues. Assessing quality and compliance saves time and resources. Review your packaging strategy regularly. It’s crucial to stay updated on changes in regulations. Your approach should reflect the evolving landscape of wood packaging standards.

Wood Packaging Material Compliance Ratings

Related Posts

-

How to Choose the Right Wood Packaging for Your Shipping Needs

-

Top 10 Benefits of Wood Packaging for Sustainable Business Solutions

-

Top Benefits of Fiber Molded Packaging for Sustainable Packaging Solutions

-

How to Choose the Best Group Packaging for Your Needs?

-

2026 Best Practices in Crating Packaging for Safe Transport?

-

How to Choose the Best Foam Cushion Packaging for Your Products