Affiliates

Affiliates

How to Choose the Best Foam Cushion Packaging for Your Products

In the ever-evolving landscape of product packaging, choosing the right materials can significantly impact both the safety of the products and the satisfaction of customers. Foam cushion packaging has emerged as a popular solution for many industries, thanks to its excellent shock absorption properties and lightweight design. As packaging expert Dr. Emily Carter emphasizes, "The right foam cushion packaging not only protects your products during transit but also enhances the unboxing experience for consumers."

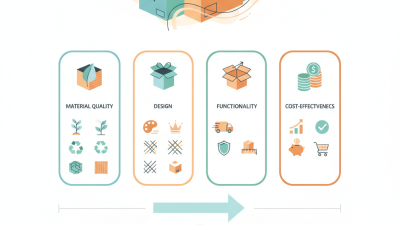

Selecting the best foam cushion packaging involves considering several key factors, such as the type of product, transportation conditions, and environmental sustainability. With advancements in foam technology, businesses now have access to a variety of options tailored to meet specific needs. This flexibility allows companies to optimize their packaging strategies while minimizing waste and ensuring that their products arrive intact.

In this guide, we will explore the essentials of selecting the appropriate foam cushion packaging for your products, highlighting the benefits it offers and the considerations that should guide your decision-making process. Whether you're a small business owner or a packaging professional, understanding how to leverage foam cushion packaging will empower you to make informed choices that benefit both your operations and your customers.

Understanding the Importance of Foam Cushion Packaging for Product Safety

Foam cushion packaging plays a pivotal role in ensuring the safety and integrity of products during transit and storage. According to a report by the International Safe Transit Association (ISTA), approximately 1.5% of products are damaged during shipping, leading to significant financial losses for businesses. Foam packaging provides a reliable solution to this issue by offering superior protection against shocks, vibrations, and temperature fluctuations, which can severely impact sensitive items. The cushioning effect of foam materials absorbs impact stress, thereby drastically reducing the risk of breakage and ensuring that products arrive at their destination intact.

Moreover, the use of foam in packaging is not only a matter of physical protection; it also contributes to a sustainable approach to product safety. A study published by the Environmental Protection Agency (EPA) highlighted that foam packaging can be recycled and reused, thus minimizing waste in landfills. This aspect becomes increasingly crucial as consumers and businesses alike are more conscious of their environmental footprint. The ability to customize foam packaging to fit specific product dimensions further enhances its effectiveness in safeguarding items against both external and internal damage. Ultimately, selecting the right foam cushion packaging is not just about protecting products; it is about enhancing brand reputation and customer satisfaction by ensuring reliable delivery of goods.

Identifying the Right Type of Foam Cushion for Your Product Needs

Choosing the right type of foam cushion packaging is crucial for protecting your products during transit and storage. Different products have unique requirements based on their size, weight, fragility, and shipping conditions. According to a report by Smithers Pira, the global market for protective packaging is expected to reach $48 billion by 2025, highlighting the increasing importance of effective packaging solutions. When identifying the right type of foam cushion, consider factors such as the density, thickness, and resilience of the foam. High-density foam provides better shock absorption for heavier, fragile items, while lower density foam might be more suitable for lighter goods.

It is also essential to evaluate the foam's compressive strength and environmental factors such as moisture resistance. A study from the International Journal of Packaging Technology describes how moisture can weaken foam, leading to diminished protection during shipping. Utilizing closed-cell foam can help mitigate moisture absorption, creating a barrier against humidity. Additionally, consider the specific needs of your products—whether they require a static-free environment or special thermal regulation. Custom foam solutions, tailored to the dimensions and weight of your items, not only ensure safety but can also enhance the unboxing experience for your customers, ultimately contributing to brand satisfaction and loyalty.

Evaluating the Different Foam Density Options Available

When selecting foam cushion packaging, one of the key factors to consider is the density of the foam. Foam density is generally categorized by how much a cubic foot of foam weighs, with higher density foams providing greater durability and support. For products that are fragile or require extra protection during transit, opting for a high-density foam can help absorb shocks and prevent damage. Conversely, lighter density foams may be suitable for less delicate items, offering sufficient cushioning without adding unnecessary weight.

Tips: When evaluating foam density, consider the nature of your products. Conduct tests to determine how different densities perform under stress. This hands-on approach can provide valuable insights into what foam density works best for your specific packaging needs. Also, keep in mind that the right combination of density and thickness can greatly influence the overall protection level.

Tips: When evaluating foam density, consider the nature of your products. Conduct tests to determine how different densities perform under stress. This hands-on approach can provide valuable insights into what foam density works best for your specific packaging needs. Also, keep in mind that the right combination of density and thickness can greatly influence the overall protection level.

In addition to density, it's essential to consider the intended use of the packaging. For static applications, medium-density foam may offer optimal cushioning, while for dynamic environments, such as shipping, higher density options typically perform better. Ultimately, the choice of foam density should align not only with your product's requirements but also with your cost considerations and logistical needs. Remember, a carefully chosen foam cushion can significantly enhance the safety of your products during transport.

Considering the Environmental Impact of Foam Cushion Materials

When selecting foam cushion packaging, it's crucial to consider not only the protection it provides but also its environmental impact. According to a 2020 report from the Environmental Protection Agency (EPA), packaging accounts for nearly 30% of municipal solid waste, and foam materials such as polystyrene, while effective at cushioning, pose significant challenges for recyclability. Using eco-friendly alternatives like bio-based foams or recycled materials can mitigate these environmental concerns. For instance, expanding the use of biodegradable cushioning has shown a 50% reduction in landfill contributions compared to traditional foam.

Moreover, shifting towards sustainable materials is not just a trend but a necessity due to increasing regulations on plastic waste. A recent study published in the Journal of Cleaner Production suggests that companies adopting environmentally friendly packaging solutions can enhance their brand perception and potentially increase customer loyalty. Approximately 66% of consumers are willing to pay more for products packaged sustainably, emphasizing the importance of foam material choices that align with eco-conscious consumer values.

Therefore, when choosing foam cushion packaging, businesses should prioritize options that minimize environmental impact while still providing adequate protection for their products.

Best Practices for Customizing Foam Cushion Packaging Solutions

When customizing foam cushion packaging solutions, it’s essential to first assess the specific needs of your products. This involves understanding the size, shape, and fragility of the items to be packaged. By conducting a thorough assessment, you can determine the appropriate type and density of foam that will provide optimal protection during transit. Using tailored foam inserts not only minimizes movement within the packaging but also significantly reduces the risk of damage, ensuring that your products arrive safely at their destination.

Incorporating design elements into your foam cushion packaging can further enhance its effectiveness. For instance, adding features such as cut-outs or custom shapes that securely cradle your products will improve fit and stability. Additionally, consider the use of eco-friendly materials for your foam solutions, aligning with sustainability practices that appeal to modern consumers. This not only bolsters your brand image but also meets the growing demand for environmentally responsible packaging options. Balancing protective functionality with aesthetic presentation can create a compelling packaging solution that leaves a lasting impression.