Affiliates

Affiliates

How to Choose the Right Wood Packaging for Your Shipping Needs

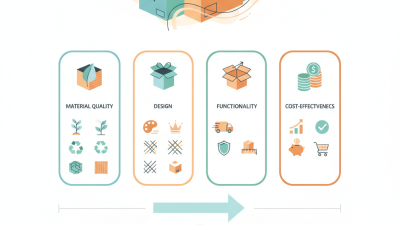

Choosing the right wood packaging for your shipping needs is a critical decision that can affect the efficiency and safety of your supply chain. According to John Smith, an expert in the wood packaging industry, “The right choice in wood packaging not only protects your product but also reflects your commitment to sustainability.” As businesses aim to balance cost-effectiveness with environmental responsibility, understanding the various options available in wood packaging becomes paramount.

Wood packaging solutions come in a variety of forms, including crates, pallets, and boxes, each serving specific purposes and requirements. The selection process should consider factors such as the nature of the product being shipped, weight considerations, and the destination's regulations regarding wood materials. Choosing the appropriate type of wood packaging ensures optimal protection during transit while also aiding in compliance with international shipping standards.

In an era where supply chain efficiency and eco-friendliness are increasingly intertwined, making informed choices about wood packaging is not only beneficial for the business but also contributes positively to the environment. By leveraging expert insights and understanding the fundamentals of wood packaging, companies can enhance their operations while meeting customer expectations.

Understanding the Different Types of Wood Packaging Materials

When it comes to selecting the right wood packaging materials for shipping, understanding the different types available is crucial. Wood packaging is commonly used for its durability and strength, making it an excellent choice for protecting goods during transit. The main types of wood packaging materials include wooden pallets, crates, boxes, and dunnage. Each type serves specific functions and offers various advantages, depending on the nature of the products being shipped.

Wooden pallets are perhaps the most widely recognized form of wood packaging, ideal for stacking and transporting goods efficiently. They allow for easy loading and unloading using forklifts and can withstand heavy weights. Crates provide additional security for fragile items, often designed to encapsulate products completely and can be customized for different sizes. Wooden boxes offer versatility, as they can be used for both storage and transportation, ensuring that items remain safe from damage. Dunnage, typically made from scrap wood, is often used to fill empty spaces within containers, cushioning items and preventing movement during transit. Each of these types of wood packaging materials meets distinct shipping needs, making it essential to choose wisely based on the specific requirements of your shipment.

Assessing Your Shipping Requirements and Product Dimensions

When choosing the appropriate wood packaging for shipping, it’s crucial to thoroughly assess your shipping requirements and product dimensions. Understanding the nature of the products you are shipping can significantly influence your packaging choices. Start by evaluating weight, fragility, and size. For instance, heavier items will require sturdier packaging to prevent damage during transit, while fragile goods may benefit from additional cushioning within the packaging. Furthermore, consider how stackable your products are, as this will affect the dimensions of the packaging you’ll need.

In addition to the characteristics of the products themselves, it’s essential to factor in shipping logistics. Assess the shipping method you will be using, as truck, rail, or air transport may have varying requirements for packaging strength and durability. Custom packaging may be necessary for irregularly shaped products or combinations of items, ensuring they remain secure throughout their journey. By taking these considerations into account, you can select wood packaging that not only protects your products but also aligns efficiently with your overall shipping strategy.

Evaluating Durability and Strength of Wood Packaging Options

When selecting wood packaging for shipping, evaluating the durability and strength of various options is crucial to ensure that your products arrive safely and intact. Different types of wood have varying levels of strength, which directly affects their ability to withstand weight and environmental factors during transit. For example, hardwoods typically offer greater durability than softwoods, making them ideal for heavy-duty applications. Additionally, considering the thickness of the wood and the design of the packaging can further enhance its strength.

Tips for evaluating wood packaging include conducting tests to assess the impact resistance and compression strength of the materials used. Look for wood that has been treated for moisture resistance to prevent warping or degradation, especially if the contents will be exposed to various environmental conditions. Another factor to consider is the wood's certification; sourcing from sustainable sources not only supports ecological balance but often guarantees a certain level of quality and durability.

Additionally, consider the weight-to-strength ratio when choosing wood packaging. Lighter options that maintain high strength can help reduce shipping costs without compromising the safety of your products. It's also advisable to analyze the return or reuse potential of the packaging to bolster sustainability practices while maintaining durability throughout its lifecycle.

Durability and Strength of Wood Packaging Options

Considering Environmental Impact and Sustainability Practices

When selecting wood packaging for shipping, it is essential to consider the environmental impact and sustainability practices associated with your choice. Wood, being a renewable resource, can be a more eco-friendly option compared to materials like plastic or metal. However, the sustainability of your packaging greatly depends on the source of the wood. Opting for wood that is certified by organizations such as the Forest Stewardship Council (FSC) ensures that the timber has been harvested responsibly, maintaining biodiversity and minimizing harm to ecosystems.

Moreover, it's crucial to evaluate the lifecycle of the wood packaging. Sustainable practices involve not only using responsibly sourced materials but also promoting reuse and recycling. Packaging designed for multiple trips or that can be easily repurposed reduces waste and lowers the overall environmental footprint. Companies should also engage with suppliers who prioritize sustainable forestry practices and are committed to reducing waste throughout their operations. By making informed choices about wood packaging, businesses can contribute to environmental conservation while still meeting their shipping needs effectively.

Cost Analysis: Budgeting for Wood Packaging Solutions

When considering wood packaging solutions for your shipping needs, budgeting plays a crucial role in the decision-making process. Analyzing the costs associated with different types of wood packaging can help you identify the most cost-effective options while ensuring safety and reliability during transit. Begin by evaluating the materials required—pallets, crates, or custom packaging may vary significantly in price. Factors such as wood type, treatment methods, and compliance with international shipping regulations can heavily influence costs.

Additionally, it’s essential to factor in ancillary costs such as labor, shipping weight, and potential storage fees. For instance, heavier packaging may increase shipping costs, while bulk purchases of standardized sizes can lead to discounts. Beyond the initial investment, consider the longevity and reuse potential of the wood packaging, as durable options may prove more economical in the long run. By conducting a thorough cost analysis, you will be better positioned to make informed decisions that align with both your shipping needs and budget constraints.