Affiliates

Affiliates

How to Choose the Best Group Packaging for Your Needs?

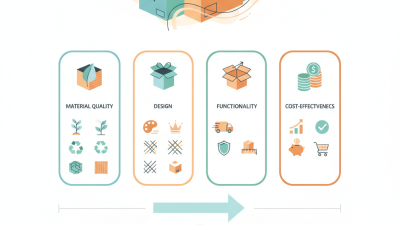

Choosing the right group packaging can significantly impact your product's success. It is essential to understand your needs and the options available. Group packaging acts as a primary layer of protection while enhancing aesthetic appeal.

Consider the nature of your products. Different items have different requirements. For fragile items, padded or reinforced packaging is ideal. Conversely, lightweight products may only need simple wrap. Evaluate whether your packaging reflects your brand’s image. Engaging designs attract customers, but functionality remains crucial.

Sometimes, companies face challenges in selecting appropriate group packaging. They may prioritize cost over quality. This can lead to damaged products and dissatisfied customers. It’s vital to strike a balance between affordability and reliability. Always be ready to reassess your choices to improve efficiency.

Understanding Different Types of Group Packaging Available in the Market

When selecting group packaging, it's essential to understand the various types available in the market. Group packaging serves multiple purposes, from enhancing product visibility to ensuring safe transit. A 2021 report by Smithers Pira highlighted that the global market for group packaging is expected to grow by 4.6% annually. This growth shows a rising demand for efficient and effective packaging solutions.

Among popular types, shrink wrapping is particularly favored. It provides a tight seal around products, preserving freshness and deterring tampering. Another option is bundling, which uses materials like paper or heat-shrink films to group items without additional rigid packaging. Despite their benefits, both methods have drawbacks. Shrink wrap can create waste, while bundling may not protect items from external damage.

**Tip:** Always consider the environmental impact of your packaging choice. Opt for recyclable materials where possible.

Tray packaging is another practical choice, especially for food items. It ensures durability and easy handling, thus optimizing supply chain logistics. However, companies must also reflect on the cost of these options. Are they justifiable against potential benefits? This analysis can guide packaging decisions wisely.

**Tip:** Don't just settle for the popular options. Research alternatives that fit your specific needs and budgets.

Evaluating Your Product and Shipping Requirements for Packaging Selection

When evaluating your product and shipping requirements for packaging selection, the stakes are high. Proper packaging ensures product safety during transit while optimizing costs. According to recent industry reports, 40% of products are damaged due to inadequate packaging. This highlights the importance of both material selection and design.

Consider the dimensions and weight of your product. Lightweight materials may reduce shipping costs. However, if your item needs extra protection, heavier materials might be necessary. Balance is key. You don't want to overspend on sturdy packaging if your product doesn't require it.

Tips: Always conduct a drop test to check sturdiness. If the product breaks, you need to rethink your choices.

Additionally, think about the shipping methods you’ll use. Different carriers have varied requirements. For instance, some might charge extra for oversized packages. Being aware of these can save you money.

Tips: Keep packaging size minimal. Smaller packages mean lower freight costs. Reassess your packaging regularly to adjust to changing shipping practices.

Assessing the Cost-Effectiveness of Various Group Packaging Options

When considering group packaging options, cost-effectiveness is a crucial factor. A recent report from the Packaging Association indicates that optimizing packaging can reduce costs by up to 25%. However, choosing the right type of packaging entails a balance between quality and price.

For instance, flexible packaging may initially seem more expensive, yet it often leads to lower shipping costs due to reduced weight. Conversely, rigid packaging might offer durability but can increase overhead significantly. The key lies in analyzing the total lifecycle costs, not just the upfront expenses.

Many companies overlook the hidden costs associated with packaging waste. About 30% of packaged items end up as waste, which can lead to loss. Conducting a thorough cost-benefit analysis is vital. This should account for both immediate costs and long-term sustainability. Evaluating multiple options can reveal more efficient and cost-effective solutions.

Sustainability Considerations in Choosing Group Packaging Solutions

Sustainability plays a crucial role in choosing group packaging solutions. Many companies now emphasize eco-friendly materials. According to a recent industry report, approximately 67% of consumers prefer sustainable packaging options. This shift reflects a growing awareness of environmental issues.

However, selecting the right sustainable packaging can be challenging. Biodegradable materials may not always provide the durability needed for transporting goods. For instance, a 2022 study revealed that 45% of brands experienced product damage when switching to green packaging. It’s essential to balance eco-friendliness with functionality.

Furthermore, the availability of recycling facilities varies significantly. Some communities may not support all types of recyclable materials, creating a disconnect. While using recycled content is beneficial, awareness and education are necessary. Brands face a dilemma: how to promote sustainability while ensuring that their packaging meets consumer expectations. This situation invites continuous evaluation of practices and materials used in group packaging.

How to Choose the Best Group Packaging for Your Needs? - Sustainability Considerations in Choosing Group Packaging Solutions

| Packaging Type | Material | Recyclability | Sustainability Score | Cost (per unit) |

|---|---|---|---|---|

| Cardboard Box | Recycled Paper | Yes | 8/10 | $0.50 |

| Biodegradable Wrap | PLA (Polylactic Acid) | Yes | 9/10 | $0.80 |

| Plastic Container | PET (Polyethylene Terephthalate) | Yes | 6/10 | $0.75 |

| Reusable Tote | Cotton | Yes | 10/10 | $1.50 |

| Compostable Film | NatureFlex | Yes | 8/10 | $0.60 |

Key Factors to Ensure Proper Protection and Presentation in Packaging

When selecting group packaging, focus on protection and presentation. Start by assessing your product's fragility. Breakable items need stronger materials, like corrugated boxes. Soft items, however, may benefit from poly bags. The right material prevents damage during transport.

Consider the packaging's visual appeal. Eye-catching design can enhance your product’s marketability. Choose colors and graphics that reflect your brand. Sometimes, simplistic designs work better. They can convey elegance. Yet, remember that the design should not overshadow functionality.

Evaluate your packaging size carefully. Too loose can lead to movement, causing damage. Too tight can create pressure, resulting in breakage. Make sure to test different sizes. Gather feedback from potential users, and reflect on their suggestions. This can improve both protection and presentation.

Related Posts

-

Top 10 Benefits of Molded Foam Packaging for Safe Shipping and Product Protection

-

How to Choose the Best Foam Cushion Packaging for Your Products

-

How to Choose the Right Wood Packaging for Your Shipping Needs

-

How to Choose the Best Custom Ecommerce Packaging for Your Online Business

-

Top 10 3PL Packaging Solutions You Should Consider for Your Business

-

10 Essential Tips for Choosing Foam Cushion Packaging for Your Products