Affiliates

Affiliates

10 Essential Tips for Choosing Foam Cushion Packaging for Your Products

In the dynamic world of product shipping and handling, selecting the right packaging is critical to ensure the safety and integrity of items during transit. When it comes to safeguarding products, foam cushion packaging stands out as an essential choice for many businesses. According to industry expert Dr. Emily Carter, a specialist in packaging materials, “The right foam cushion packaging not only protects your products but also enhances customer satisfaction by ensuring that items arrive in perfect condition.”

With a wide variety of foam materials and designs available, the decision-making process can be daunting for manufacturers and retailers alike. As businesses strive to optimize their packaging solutions, understanding the key factors that influence the effectiveness of foam cushion packaging becomes increasingly important. From evaluating the dimensions and weight of products to considering environmental impacts, the selection process can significantly affect both the bottom line and customer experience.

In this article, we will explore ten essential tips for choosing foam cushion packaging tailored to your products' needs. By following these guidelines, you can make informed decisions that will not only protect your merchandise but also contribute to sustainability and cost-effectiveness in your packaging strategy.

Understanding the Importance of Foam Cushion Packaging

Foam cushion packaging plays a crucial role in protecting products during transit and storage. Its ability to absorb shock and reduce impacts makes it an invaluable choice for various items, from fragile electronics to delicate glassware. This type of packaging not only safeguards the integrity of the products but also minimizes the risk of returns and damage claims. Businesses can enhance their customer satisfaction by ensuring that products arrive in pristine condition, ultimately reflecting positively on their brand.

Moreover, foam cushion packaging is versatile and customizable, allowing for a tailored fit to specific products. This not only optimizes space in shipping containers but also reduces material waste, contributing to more sustainable packaging practices. Understanding the importance of foam cushion packaging helps businesses recognize that investing in high-quality cushioning can lead to cost savings and increased efficiency in logistics. By carefully selecting the appropriate foam materials and designs, companies can create a reliable packaging solution that supports both product safety and their environmental goals.

Types of Foam Cushion Materials and Their Benefits

When selecting foam cushion materials for packaging, understanding the various types available and their respective benefits is essential to ensure product safety and optimal protection during transportation. The most common types of foam used in packaging are polyethylene foam, polyurethane foam, and expanded polystyrene (EPS). According to industry reports, the global foam packaging market is expected to reach approximately $50 billion by 2026, driven by the increasing demand for protective packaging solutions across various sectors, including consumer electronics and e-commerce.

Polyethylene foam is particularly favored for its lightweight and water-resistant qualities, making it ideal for protecting sensitive items during shipping. Its closed-cell structure provides excellent cushioning properties while preventing moisture ingress. On the other hand, polyurethane foam is known for its superior shock absorption and flexibility, adapting to diverse product shapes. This adaptability makes it suitable for high-value goods, efficiently minimizing the risk of damage. Furthermore, expanded polystyrene (EPS) is widely used due to its cost-effectiveness and thermal insulation capabilities, making it a popular choice for perishable goods and temperature-sensitive items.

While each foam type offers unique attributes, selecting the right material ultimately hinges on the specific requirements of the product being packaged, such as weight, fragility, and environmental considerations. Manufacturers are increasingly prioritizing sustainable options, with a report from Smithers stating that eco-friendly foam alternatives are projected to grow by 20% over the next five years. Thus, making informed choices about foam cushion packaging materials not only enhances product protection but also aligns with sustainability goals.

Factors to Consider When Selecting Foam Packaging

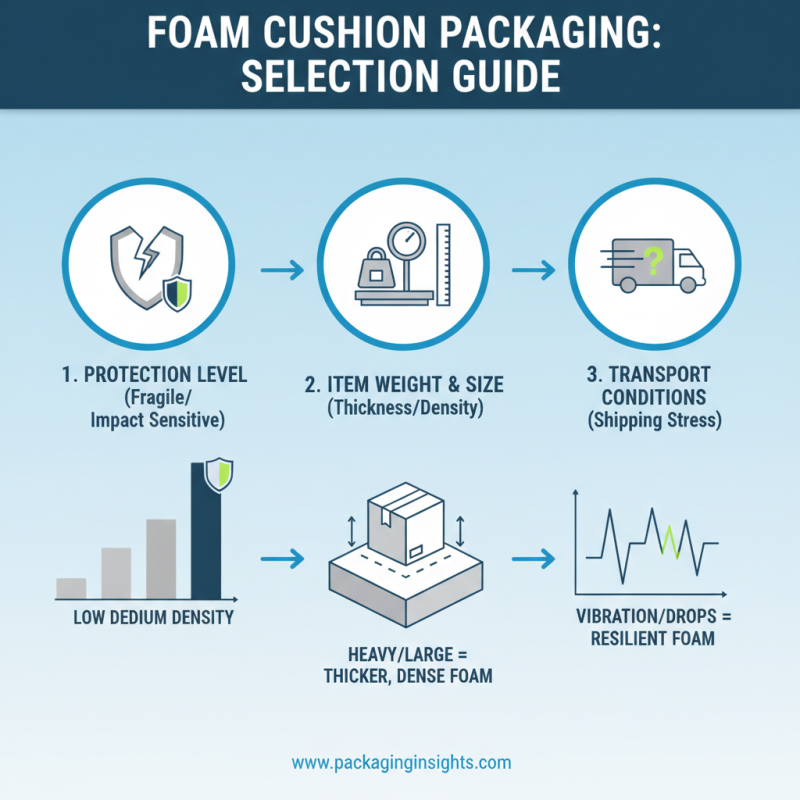

When selecting foam cushion packaging for your products, several key factors should guide your decision. First and foremost, it's essential to consider the level of protection your items require. Products that are fragile or sensitive to impacts will benefit from high-density foam, which offers superior cushioning. Assessing the weight and dimensions of your items will help determine the thickness and density of the foam needed to prevent damage during transport.

Another crucial aspect is the environmental impact of your packaging materials. Opting for eco-friendly foam options can enhance your brand's sustainability efforts and appeal to environmentally conscious consumers. Additionally, the cost of foam packaging plays a significant role in your selection process. Balancing quality and budget is vital; while investing in top-notch materials may seem costly, the long-term savings from reduced product returns and damage can justify the expense. By carefully evaluating these factors, businesses can select foam cushion packaging that not only protects their products effectively but also aligns with their operational goals and environmental responsibilities.

Measuring Product Dimensions for Proper Foam Fit

When it comes to choosing foam cushion packaging, accurately measuring product dimensions is critical to ensuring a proper fit and optimal protection during shipping. According to a recent industry report by the International Safe Transit Association (ISTA), nearly 30% of damaged goods during transit can be attributed to inadequate packaging solutions. To avoid these losses, businesses must take precise measurements of their products, including length, width, and height, as well as account for any irregular shapes or fragile components.

In addition to basic dimensions, it is essential to consider the intended foam thickness and compression properties. A study from the Packaging Machinery Manufacturers Institute (PMMI) highlights that the right foam density can significantly affect protection levels, with high-density foam offering better cushioning compared to low-density options. Therefore, businesses should not only obtain accurate measurements but also select foam formulations that provide the required durability and resilience to withstand shocks and vibrations encountered during transportation. By prioritizing accurate dimension assessment, companies can create effective packaging solutions that minimize product damage and enhance customer satisfaction.

Measuring Product Dimensions for Proper Foam Fit

Cost-Effectiveness and Sustainability in Foam Packaging Choices

When selecting foam cushion packaging, cost-effectiveness and sustainability are crucial factors that should guide your decision-making process. Foam packaging, often associated with high-quality protection of products, can also be implemented in a manner that is economically viable. By conducting a thorough analysis of your packaging needs, you can select foam materials that offer both adequate protection and competitive pricing. Look for options that balance durability with cost, ensuring you do not compromise on product safety while keeping expenses in check.

Sustainability should also be at the forefront of your packaging choices. The increasing emphasis on environmental responsibility means that opting for eco-friendly foam options can enhance your brand image while contributing positively to the planet. Consider biodegradable or recyclable foam materials that reduce waste and minimize environmental impact. Additionally, sourcing foam from suppliers that prioritize sustainable practices can further align your operations with green initiatives, making a lasting positive impression on environmentally-conscious consumers. By integrating cost-effective methods with sustainable materials, you can create an efficient packaging strategy that meets both financial and ethical standards.

Related Posts

-

How to Choose the Best Foam Cushion Packaging for Your Products

-

Top 10 Benefits of Molded Foam Packaging for Safe Shipping and Product Protection

-

Top 10 Benefits of Wood Packaging for Sustainable Business Solutions

-

How to Choose the Best Custom Ecommerce Packaging for Your Online Business

-

Best Clean Room Packaging Solutions for Ensuring Product Safety and Quality

-

Top 5 3PL Packaging Trends to Watch in 2025 for Your Business