Affiliates

Affiliates

Top 10 Benefits of Molded Foam Packaging for Safe Shipping and Product Protection

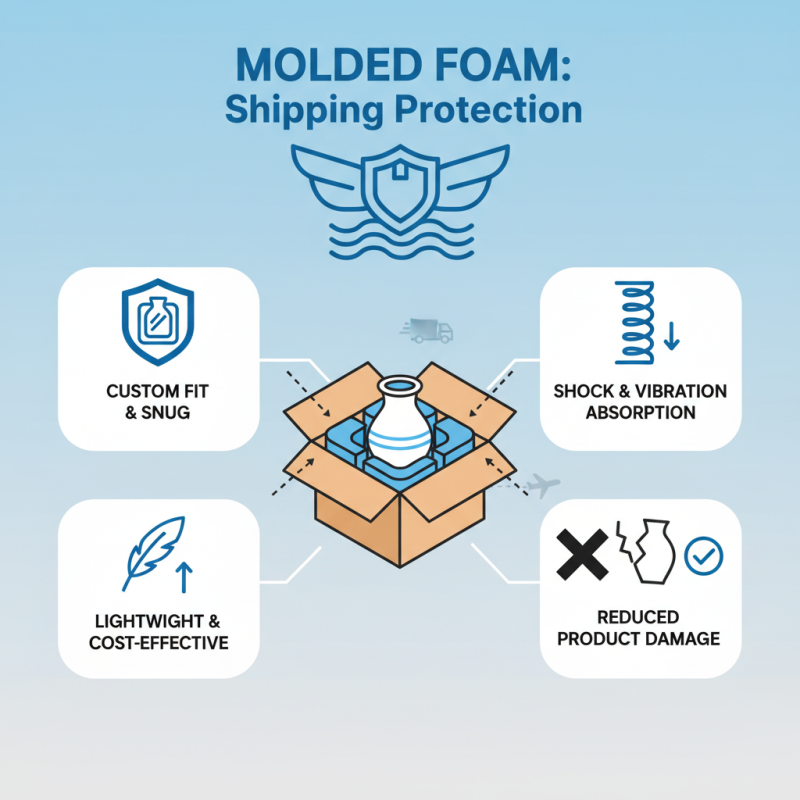

In today's fast-paced e-commerce environment, ensuring the safe transit of products has never been more crucial. One effective solution that has gained prominence is molded foam packaging. This innovative material not only provides superior protection during shipping but also offers numerous benefits that enhance overall product security. With its unique ability to conform to various shapes and sizes, molded foam packaging acts as a customized protective shell that minimizes movement and absorbs shocks during transit. As businesses increasingly prioritize sustainability, this packaging choice also presents an eco-friendly alternative, often made from recyclable materials.

Moreover, molded foam packaging is designed to reduce the risk of damage, which can lead to costly returns and dissatisfied customers. Its lightweight nature contributes to lower shipping costs while maintaining robust protection for fragile items. In this article, we will explore the top 10 benefits of molded foam packaging, highlighting how it not only safeguards products but also streamlines logistics, enhances brand reputation, and meets the ever-evolving demands of consumers. By leveraging the advantages of molded foam packaging, companies can ensure that their products arrive in perfect condition, ultimately driving customer satisfaction and loyalty.

Types of Molded Foam Packaging and Their Uses

Molded foam packaging has emerged as a critical component in ensuring safe shipping and product protection across various industries. This type of packaging is primarily made from polystyrene (EPS), polyurethane, and polyethylene foams, designed to cushion and shield products from damage during transit. Each material offers unique properties that cater to different types of products. For example, EPS is lightweight and offers excellent shock absorption, making it ideal for electronic devices and fragile items, while polyurethane foam provides superior durability and is often used for automotive parts and high-end consumer goods.

In addition to the material types, molded foam packaging can be customized in various shapes and sizes. This versatility enables manufacturers to create inserts that fit their products snugly, reducing movement within the package and minimizing the risk of damage. According to recent industry analyses, approximately 60% of businesses that utilize molded foam notice a significant decrease in product damage during shipping, highlighting its effectiveness in safeguarding items. Additionally, molded foam is recyclable and environmentally friendly, addressing sustainability concerns prevalent among consumers today.

Tips: When selecting molded foam packaging, consider the specific needs of your product. Evaluate factors like weight, fragility, and shipping conditions to choose the right foam type. Additionally, always opt for recyclable materials to contribute positively to environmental sustainability while maintaining product safety.

The Role of Molded Foam in Product Protection During Shipping

Molded foam plays a crucial role in ensuring the safe shipping and protection of various products. This innovative packaging solution is designed to conform precisely to the shape of the item it is protecting, providing a snug fit that minimizes movement during transit. By absorbing shocks and vibrations, molded foam significantly reduces the risk of damage to fragile items. Its lightweight nature also means that it does not add unnecessary weight to the shipped products, helping businesses to keep shipping costs down while still maintaining high standards of protection.

Additionally, molded foam offers excellent thermal insulation, making it an ideal choice for shipping temperature-sensitive items. This feature ensures that products remain within their optimal temperature range throughout their journey, preventing spoilage or degradation. Moreover, molded foam is resistant to moisture and dust, further safeguarding the integrity of the items packed within. With its ability to be customized into various shapes and sizes, molded foam packaging not only enhances product protection but also improves the overall unboxing experience for customers, reinforcing the value of the products they receive.

Cost-Effectiveness of Molded Foam Packaging Solutions

Molded foam packaging is gaining popularity for its cost-effectiveness and superior protective qualities. One of the primary financial advantages of molded foam is its ability to reduce damage during transit. By perfectly fitting around products, it minimizes the risk of breakage and returns, ultimately saving businesses money in replacement costs and lost sales. Additionally, molded foam is lightweight, which helps to lower shipping expenses compared to heavier packaging alternatives. This balance of lightweight materials and robust protection makes it a smart choice for businesses looking to optimize their logistics budget.

When considering molded foam solutions, here are a couple of tips to enhance cost-effectiveness: First, evaluate the density of the foam material. Choosing the appropriate density based on your product's fragility can reduce excess material consumption while still providing adequate protection. Second, look into bulk purchasing options; suppliers often offer discounts for larger orders, allowing you to maximize savings on your packaging needs. By strategically selecting the right molded foam and supplier, you can effectively manage costs while ensuring that your products reach customers safely.

Environmental Impact of Molded Foam Packaging Materials

Molded foam packaging has gained popularity not only for its protective qualities in shipping but also for its environmental considerations. The manufacturing process of molded foam often incorporates recycled materials, significantly reducing the consumption of virgin plastics and minimizing waste. Additionally, many companies are now focusing on biodegradable alternatives to traditional foam, which can help lessen the long-term environmental impact associated with plastic pollution. By shifting towards sustainable materials, manufacturers can ensure that their packaging solutions align with eco-friendly practices, contributing to a circular economy.

Moreover, the lightweight nature of molded foam packaging can lower transportation emissions, as less energy is required to transport lightweight materials compared to heavier alternatives. This aspect not only supports sustainability but can also result in cost savings for businesses. Furthermore, advancements in foam technology are leading to the development of foam products that are not only protective but also easy to recycle, making it simpler for consumers and businesses to dispose of packaging responsibly. These factors emphasize the potential for molded foam packaging to serve as an environmentally sound option in the quest for safer shipping methods and product protection.

Enhancing Customer Experience with Molded Foam Packaging Design

Molded foam packaging has become a pivotal element in enhancing customer experience, particularly in the realm of safe shipping and product protection. The customized design of molded foam allows for precise fitting around products, ensuring they remain secure during transit. This tailored approach not only minimizes the risk of damage but also provides customers with a sense of assurance that their purchases will arrive in pristine condition. When customers see that their items are well-protected, their confidence in the brand increases, fostering loyalty and encouraging repeat purchases.

Moreover, the aesthetic appeal of molded foam packaging can significantly amplify the unboxing experience. By incorporating unique shapes and vibrant colors, brands can create a memorable impression right from the moment a package is opened. This thoughtful design element transforms a simple delivery into an engaging event, allowing customers to appreciate the attention to detail and care put into the packaging. Such positive experiences can lead to higher customer satisfaction and positive reviews, ultimately boosting a brand's reputation in a competitive market.

Related Posts

-

How to Choose the Best Foam Cushion Packaging for Your Products

-

Why Testing Packaging is Essential for Product Success and Quality Assurance

-

Top 10 Benefits of Wood Packaging for Sustainable Business Solutions

-

How to Choose the Right Wood Packaging for Your Shipping Needs

-

How to Choose the Best Custom Ecommerce Packaging for Your Online Business

-

Best Clean Room Packaging Solutions for Ensuring Product Safety and Quality