Affiliates

Affiliates

Why Testing Packaging is Essential for Product Success and Quality Assurance

In the competitive landscape of consumer goods, the integrity and quality of packaging play a pivotal role in ensuring product success. A comprehensive study conducted by the Packaging Association revealed that proper packaging testing can reduce product returns by as much as 70%, underscoring the critical importance of "testing packaging" in the production process. As businesses strive to enhance customer satisfaction and minimize costs, the need for rigorous testing protocols becomes increasingly apparent. Indeed, a report from the Institute of Packaging Professionals indicates that 30% of a product's first impression is influenced by its packaging, highlighting the necessity for robust quality assurance measures.

Moreover, the economic implications of ineffective packaging can be severe. The Food and Drug Administration (FDA) estimates that defective packaging costs the food and beverage industry over $1 billion annually due to spoilage and waste. This statistic underlines the importance of investing in testing packaging to ensure compliance with safety standards and minimize financial losses. As brands face growing scrutiny from consumers demanding higher-quality and environmentally friendly packaging, the significance of thorough testing cannot be overstated. By prioritizing packaging quality and implementing effective testing strategies, companies can not only protect their products but also bolster their market position in an increasingly discerning marketplace.

The Importance of Packaging Testing in Product Development

Testing packaging is a critical component of product development, ensuring that products not only reach consumers safely but also maintain their quality throughout the supply chain. When a product is packaged, it must withstand various challenges, such as impact, vibration, and environmental factors. Rigorous packaging testing assesses these conditions, helping developers identify weaknesses in the packaging design and materials before the product launches into the market. By catching potential issues early in the development process, companies can prevent costly recalls or damage that could tarnish their reputation.

Moreover, effective packaging testing plays a significant role in compliance with industry standards and regulations. Adhering to these guidelines ensures that packaging is not only functional but also sustainable and safe for consumers. Testing can also uncover valuable insights into consumer preferences, as packaging often serves as a vital touchpoint between the product and the buyer. By evaluating how different materials and design choices resonate with the target audience, product developers can make informed decisions that enhance both the functionality and aesthetic appeal of their packaging, ultimately contributing to the product's overall success in the marketplace.

Key Objectives of Testing Packaging for Product Success

Testing packaging is a critical component in the lifecycle of a product, directly impacting both product success and quality assurance. According to a study by Smithers Pira, package testing can reduce the overall risk of product failure by up to 30%. This reduction is essential as a failure in packaging not only compromises the product’s integrity but can also lead to significant financial losses and damage to brand reputation. Effectively employed testing protocols can ensure that packaging meets rigorous safety and performance standards, ultimately enhancing customer satisfaction and driving repeat purchases.

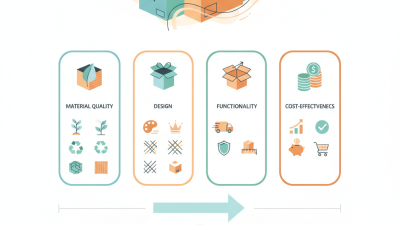

The key objectives of testing packaging include ensuring protection, compliance, and functionality. Protective testing evaluates a package's ability to maintain its integrity under various conditions, including transit and storage, which is vital as approximately 10% of products are damaged during transport, as reported by the International Safe Transit Association. Compliance testing verifies that packaging materials meet relevant regulatory standards, which is increasingly important in a global market where regulations vary widely. Lastly, functionality testing assesses user interaction and ease of use, proving that well-designed packaging can lead to a better customer experience and increased market share. Effective testing of packaging is not merely an option; it is a prerequisite for achieving product excellence and sustaining competitive advantage in the marketplace.

Testing Packaging: Key Objectives for Product Success

Methodologies Used in Packaging Testing and Quality Assurance

Packaging testing is a critical component of quality assurance, ensuring that products are protected and presented effectively throughout their lifecycle. Various methodologies are employed to evaluate the durability, functionality, and safety of packaging. One common approach is the physical testing of packaging materials, which includes assessments such as impact resistance, compression testing, and drop tests. These methods help identify potential weaknesses in design or materials that could compromise the product during transportation or storage.

Additionally, seal integrity testing is essential to guarantee that packages maintain their contents securely. Techniques such as vacuum testing and dye penetration tests are used to verify that seals are intact and reliable. Furthermore, environmental testing simulates real-world conditions, such as temperature fluctuations and humidity, to assess how packaging performs under adverse situations. By incorporating these methodologies into the packaging development process, companies can enhance the reliability of their products, reduce returns, and ultimately achieve greater customer satisfaction.

Common Challenges in Packaging Testing and Solutions

Packaging testing is crucial in ensuring that products reach consumers in optimal condition. However, companies often face various challenges during the testing process. One common hurdle is the variability in materials. Different packaging materials can respond unpredictably to stress, temperature changes, and environmental factors, leading to potential failures. To address this, employing a standardized testing protocol that evaluates the performance of diverse materials under controlled conditions can provide reliable insights and minimize risks.

Another significant challenge is the integration of testing processes within the production timeline. As many companies rush to bring products to market, quality assurance tasks may be sidelined. This can lead to inadequate testing and subsequent issues post-launch. Implementing a phased testing schedule ensures that packaging is assessed at multiple stages of development, allowing for timely adjustments and reducing the likelihood of delays in product release. By prioritizing comprehensive testing within the production cycle, businesses can enhance both product quality and consumer satisfaction.

The Impact of Packaging Quality on Consumer Perception and Brand Trust

The quality of packaging plays a pivotal role in shaping consumer perception and establishing brand trust. When customers encounter a product, the first point of contact is often its packaging. High-quality packaging not only protects the product but also enhances its aesthetic appeal, conveying a sense of care and professionalism. This visual impact can significantly influence a consumer's initial impressions and choices, making them more likely to perceive the product as reliable and worth purchasing. Flimsy or poorly designed packaging, conversely, can lead to negative associations, causing potential buyers to question the integrity and value of the product inside.

Moreover, effective packaging serves as a representation of brand identity. It communicates core values and differentiates a brand from its competitors. When packaging is consistent and thoughtfully designed, it fosters a connection between consumers and brands, boosting their loyalty and trust. A well-packaged product signals to the consumer that the brand prioritizes quality not just in its product but also in every aspect of the purchase experience. As such, investing in testing and improving packaging should be seen as a crucial element of a successful marketing strategy, directly affecting how consumers perceive both the product and the brand as a whole.

Why Testing Packaging is Essential for Product Success and Quality Assurance - The Impact of Packaging Quality on Consumer Perception and Brand Trust

| Packaging Type | Consumer Perception (%) | Brand Trust (%) | Quality Assurance Metrics |

|---|---|---|---|

| Plastic | 75 | 70 | Pass: 95%, Fail: 5% |

| Glass | 85 | 80 | Pass: 98%, Fail: 2% |

| Cardboard | 70 | 75 | Pass: 90%, Fail: 10% |

| Metal | 80 | 85 | Pass: 97%, Fail: 3% |

| Biodegradable | 78 | 74 | Pass: 92%, Fail: 8% |

Related Posts

-

How to Choose the Best Foam Cushion Packaging for Your Products

-

How to Choose the Right Wood Packaging for Your Shipping Needs

-

Best Clean Room Packaging Solutions for Ensuring Product Safety and Quality

-

Top 10 Benefits of Wood Packaging for Sustainable Business Solutions

-

How to Choose the Best Custom Ecommerce Packaging for Your Online Business